A number of technical knowledge of low temperature ultrafine pulverizer

A number of technical knowledge of low temperature ultrafine pulverizer

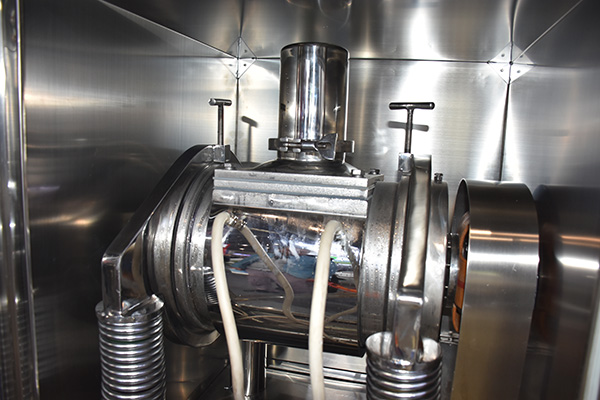

The low-temperature superfine pulverizer adopts automation technology and has a single machine with multi-function automation (FMC flexibility), which makes the production of small batches of drugs as simple as mass production line production. Clean technology, designed and manufactured in strict accordance with GMP standards, can meet the special requirements of pharmaceutical powder equipment. The parts in contact with the material are all polished stainless steel, and its material is the general material of international medicine and food machinery (it can also be changed to other metal materials according to user requirements), avoiding heavy metals such as arsenic, cadmium, mercury, lead, and copper.

Advantage performance:

The fully enclosed non-grading technology, the fully enclosed multi-grinding and non-sieve technology used to preserve the medicinal ingredients, effectively avoids segregation and loss of medicinal ingredients, and environmental pollution due to dust overflow. Compression micro-pulverization technology uses high-speed impact force and shear force to improve the pulverization efficiency and effect, so that the material is squeezed, kneaded and torn by the medium in the mill cylinder, shortens the pulverization time and improves the pulverization efficiency; at the same time Because the material is fluidized and each particle has the same stress state, its self-viscous effect can make the finished product form a uniformly dispersed and compounded particle cluster, increase the density and increase the bioavailability, and improve the micro-pulverization effect and technology . Dynamic optimization technology, according to the different characteristics of the material, while ensuring the improvement of the efficiency and effect of micro-pulverization, optimization and adaptation technology. Mechatronics technology: A technology that achieves high performance and high level of equipment, reduces manual consumption, ensures stable and controllable quality of finished products, and avoids unstable quality and contamination due to excessive manual intervention.

Technical field:

The low-temperature ultra-fine pulverizer adopts a number of advanced technologies and uses high-speed impact and shear forces to make the material in the grinding cylinder subject to high-acceleration impact, discussion, extrusion, and cutting of the medium, which can achieve the ideal in a short time Crushing effect. The material is fluidized in the crushing process, so that each particle has the same stress state, and achieves the effect of mixing (dispersion) while crushing. After adjusting the acceleration and other parameters, the operation with the purpose of grinding or mixing (mixing) as the main goal can be realized.