These suggestions are very important when selecting ultra-fine crusher

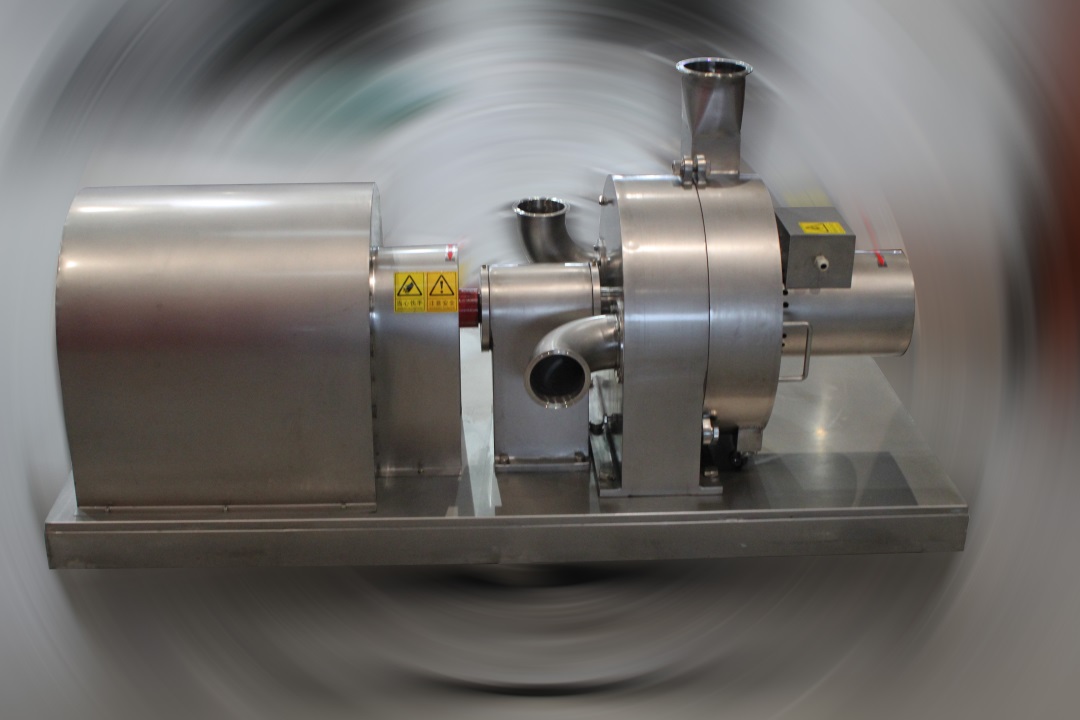

Ultra micro pulverizer has the advantages of improving the dissolution rate and amount of effective components and improving the uniformity of products. It is of great significance for the development of traditional Chinese medicine industry. The machine is more and more popular in the traditional Chinese medicine market, and has gradually become an ideal equipment for crushing traditional Chinese medicine materials. However, some details need to be paid attention to when selecting the crusher.

1. Find the right model: you need to clarify your needs, find the right model, then narrow the scope, compare several goods, and gradually eliminate the selection of equipment suitable for you.

2. Environmental requirements: the requirements for equipment environment should be considered from many aspects. For example, whether there are appropriate site conditions; Whether the vibration and noise of the equipment meet the standards, etc.

3. Material requirements: when selecting equipment, it is necessary to consider the characteristics of materials to be crushed, process fineness requirements, microbial limit requirements, whether the output matches, crushing requirements of special materials, etc. Mismatched equipment naturally can not achieve satisfactory crushing effect.

4. Process: the processing capacity of the crusher needs to be considered; Requirements for particle size and particle size distribution of crushed drugs. In addition, at present, the market has high requirements for crushing control and environmental sanitation, and the selected ultra-fine crusher equipment should meet GMP standards. Some drugs are tough, sticky, oily and moisture, and difficult to crush. Therefore, we should carefully check their process and effect when purchasing.

The machine cannot be used continuously for a long time, and the time of each startup shall not exceed 5 minutes. If the processing quantity is large, it shall be used at intervals to prevent overheating of the bearing and damage to the motor. After the operation every day, make the machine run by air for 2min and suck the remaining materials. After shutdown, open the machine cover to check whether the parts are damaged, and close the machine cover after removing the residual materials.