Only by doing these things well can the installation of traditional Chinese medicine superfine pulve

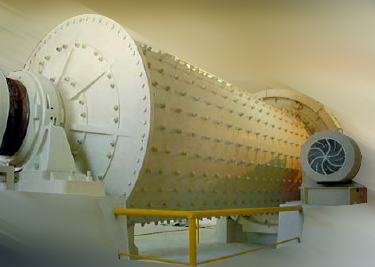

The ultra-fine pulverizer of traditional Chinese medicine is an equipment for ultra-fine pulverization of dry materials in the form of air separation, heavy pressure grinding and shearing. It is composed of cylindrical crushing chamber, grinding wheel, grinding rail, fan and material collection system.

The ultra-fine crusher is installed on the flat concrete structure foundation and is not fixed with anchor bolts. During installation, pay attention to the verticality between the main body and the horizontal. After installation, check whether the bolts at all parts are loose and whether the main chamber door can be fastened. If so, fasten it in time. Let's talk about the installation and commissioning of the crusher in detail.

Installation and commissioning of traditional Chinese medicine superfine pulverizer:

1. After the pulverizer is in place, it must be placed stably and fixed with anchor screws.

2. Before commissioning, clean the inner cavity of the machine and lock the front cover with a star handle.

3. After the power is turned on, pay attention to its phase sequence to make the main shaft rotate in the direction shown.

4. During commissioning, pay attention to whether the machine has abnormal noise, so as to timely signal the vehicle for inspection.

The power line and control switch shall be configured according to the power system of the crusher. After the construction is checked, the no-load commissioning shall be carried out. The production can be started after the commissioning is normal.

During the production of traditional Chinese medicine superfine pulverizer, the temperature of the bearing must be checked frequently. When the temperature rises above 50 ℃, the water cooling pipe should be connected to cool the bearing. When the temperature rises to 90 ℃, stop the machine for inspection, find out the cause and eliminate the fault.

When the new machine is running, the drive belt is easy to stretch. Pay attention to adjusting the appropriate tightness of the belt to ensure the working life of the belt. Vulnerable parts shall be inspected frequently and replaced in time to ensure production quality and production capacity. The wear of the blade shall be checked frequently. If the productivity decreases and the particle size becomes coarse after wear, it shall be replaced immediately after wear.