Why should ultra-fine low-temperature crusher be cooled and crushed, and what are the benefits?

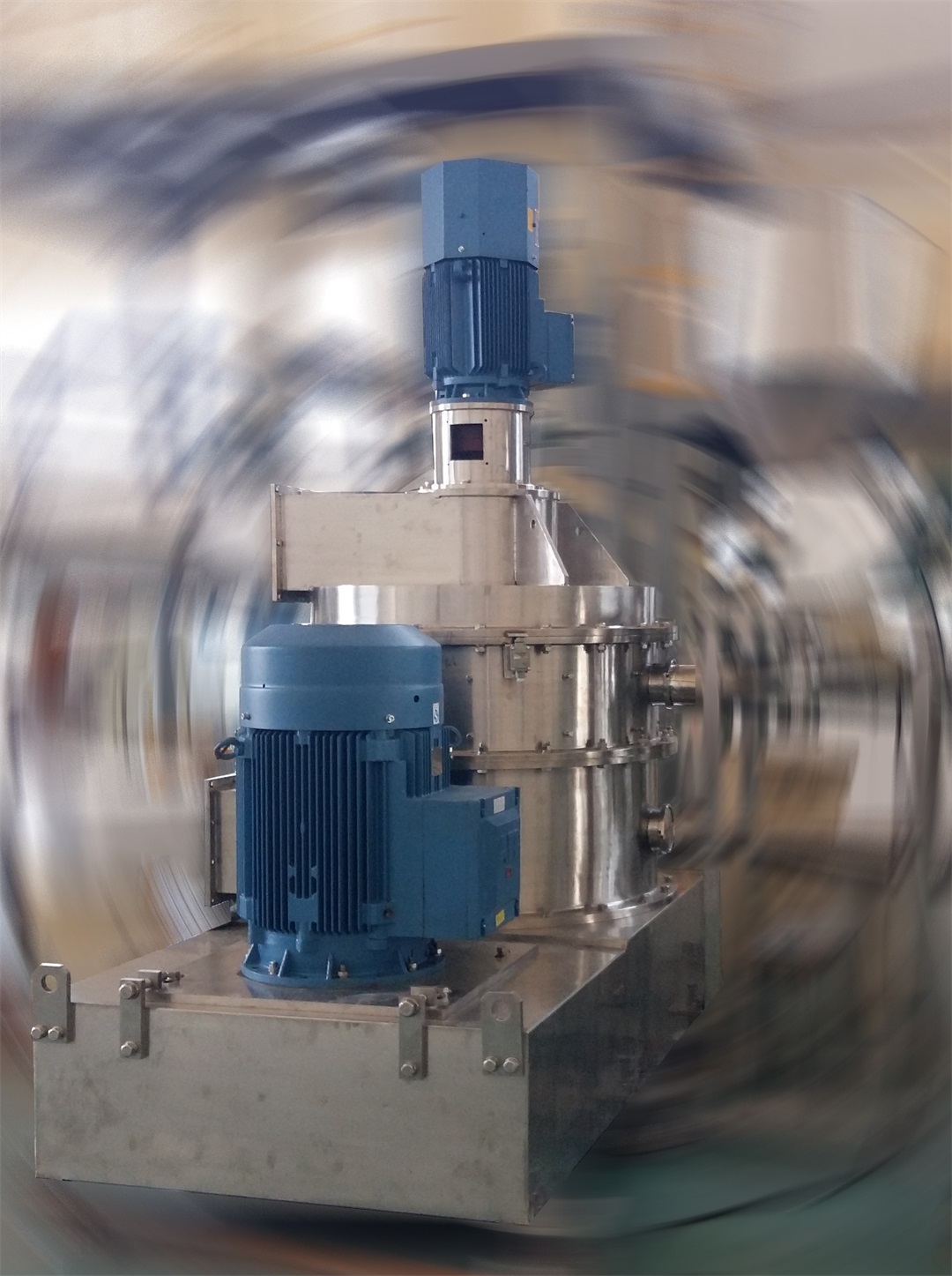

The ultra-fine low-temperature pulverizer is an integral type. The whole system is carried out in a closed and insulated body. The cold air of minus 15-80 degrees is supplied by the refrigerator. The crushed materials are brittle and easy to be crushed at low temperature through cooling, and then enter the chamber of the mechanical pulverizer. Through the high-speed rotation of the impeller, the materials and blades, toothed discs, materials and materials repeatedly impact, collide and shear each other, Under the comprehensive action of friction, so as to achieve the crushing effect.

The main advantage of ultra-fine pulverizer is that the ultra-fine comminuted food is absorbed quickly in the human body. The effective components in medicinal materials are usually distributed in cells and intercellular matrix, mainly in cells. If crushed in a conventional way, its single particle is usually composed of several or dozens of cells, the wall breaking rate of cells is low, and the corresponding effective components are difficult to be fully absorbed by the human body.

Due to the large particles of the active ingredient particles, the possibility of adsorption on the intestinal wall is small. The peristaltic mode of the small intestine causes the concentration of the active ingredient around the cell to be higher than that on the intestinal wall, which makes it difficult to improve the concentration difference inside and outside the cell wall and slows down the release rate. A considerable part of the active components of the particles are excreted before they are fully released, which reduces the bioavailability of the drug.

The purpose of cooling the ultra-fine low-temperature pulverizer:

1. It can reduce the impact toughness and elongation at break of materials and make them easy to be crushed.

2. It can counteract the local heat and temperature rise during crushing and maintain a low temperature state.

3. Greatly reduce the crushing heat and increase the crushing output of Baidu. Whether the material must be frozen to the embrittlement temperature to be effectively crushed. After experimental research, the answer is No.

So, what is the suitable temperature for the ultra-fine low-temperature crusher to freeze? Experiments show that it can be frozen to a certain temperature between the two temperatures of obvious weakening of elasticity and local heating during crushing, which does not affect the crushing effect and complete hardening. The key to the realization of this method is to eliminate the local impact, friction and heat during crushing.