Powder fusion technology is a new composite material processing technology, which is to process two or more powders into a new powder material by the mechanochemical effect generated by the mechanical force acting on the powder surface.

Characteristics of powder fusion modification production process:

Suitable for coating of nano particles to micro particles

The system can control the temperature through heat or refrigerant;

Inert gas can be used to prevent material oxidation or fire and explosion

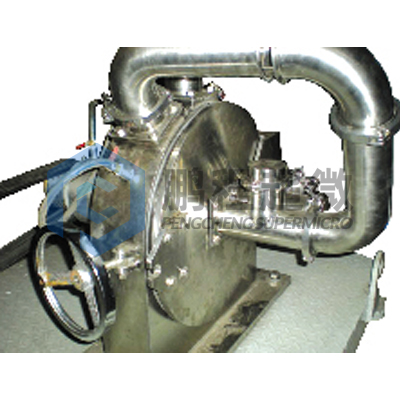

working principle

The mechanical force generated by the high-speed rotation of the rotor is used to quickly disperse the powder, and the powder is continuously impacted, sheared, compressed, and rubbed in a closed circulation system according to the application requirements, so that the powder is continuously fused. It is also possible to spray modifiers, and use dry particle surface modification and composite technology to obtain nano/micro composite materials or nano/nano composite materials by the method of preparing inorganic composite materials. It is also possible to perform coating modification, encapsulation or coating or sustained release, spheroidization, etc. of the spheroidization treatment of amorphous particles. Such as nano-modification of micron particles, titanium dioxide coating of mica and calcium carbonate, pitch coating or spheroidization of graphite, slow release control of drugs or catalysts, etc.

Application field

Suitable for powder materials (such as titanium dioxide coated diatomaceous earth, titanium dioxide coated pearl mica, titanium dioxide coated attapulgite, titanium dioxide and sepiolite, titanium dioxide and composite materials, zinc oxide/magnesium hydroxide, zinc oxide/aluminum hydroxide , And magnesium-aluminum composite materials, wollastonite and calcium carbonate, aluminum silicate coated wollastonite, zinc oxide coated kaolin, titanium dioxide coated kaolin, etc.) coating modification, encapsulation or coating or slow release, Sphericalization and other processing. Such as nano-modification of micron particles, titanium dioxide coating of mica and calcium carbonate, pitch coating or spheroidization of graphite, slow release control of drugs or catalysts, etc.

Specification model

|

Model |

BSM-1 |

BSM-2 |

BSM-3 |

BSM-4 |

|

Power (kw) |

4 | 11 | 22 | 45 |

|

Processing capacity g |

100 | 400 | 800 | 1600 |