The spiral high-temperature steam jet mill is used in the titanium dioxide production line, because it shows the most efficient and economical depolymerization effect in terms of dispersibility, opacity, color strength and other final properties, as well as various appearance and performance. Advantage. The micro-powder machine is driven by steam, which is very suitable for the powder removal and particle size reduction of inorganic pigments.

Features and advantages

Can reach nanometer level

Good depolymerization effect: ensure the dispersibility of the reunion tio2

Can be operated under high pressure dry steam and hot air conditions

Ceramic wear-resistant protection and pollution-free design,

Easy to clean

Good repeatability of product inspection results

working principle

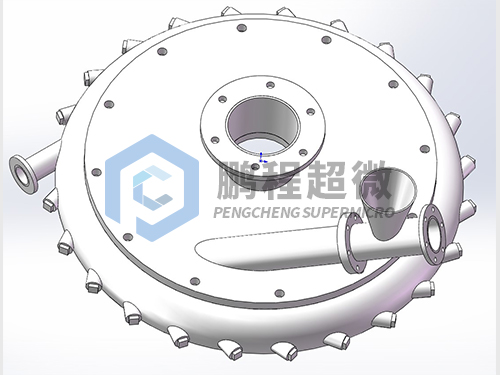

FEM-S spiral steam micro powder jet mill uses superheated steam to be applied to the feeding part and grinding part of the machine under high temperature and high pressure. The steam energy applied to the grinding part generates a rapidly rotating vortex in the grinding chamber. The agglomerated titanium dioxide feed is pushed into the grinding chamber, passing through the feed part tangent to the jet of steam, when it is drawn into the vortex and rotates with it. Particles and particles impact and collide with each other, and the size becomes smaller. The centrifugal force causes the larger particles to rotate in the airflow to further reduce the size, until their size becomes smaller, they can move to the center of the micronizer, and exit the mill with the airflow. These particles are collected into nano and sub-nano finished products, or transported to the next processing link.

use

It is widely used in dry ultra-fine grinding of small particle size, increased surface area and narrow particle size distribution, suitable for various brittle, crystalline, heat-sensitive, medium and low hardness materials. Used in chemical, pharmaceutical, food and other industries, with high yield and no dust spillage.

Specification model

|

Specifications |

FEM-S01 |

FEM-S02 |

FEM-S03 |

FEM-S04 |

FEM-S05 |

FEM-S06

|

FEM-S07

|

|

Product size: um |

0.3~45 |

||||||

|

Production capacity kg/h |

1~20 |

5~50 |

10~120 |

40~260 |

80~600 |

200~1500

|

450~3000

|

|

Pressure Mpa |

1.0~10 |

||||||

Note: Based on calcium carbonate, the above is for reference only.