Jet-s steam mill is a technological innovation in which the jet mill uses superheated dry steam as the grinding medium.

The high temperature steam jet mill can almost grind products of various hardness.

The built-in airflow classifier can be adjusted to the required particle size by the frequency converter in the mill, and the particle fineness can reach the sub-micron range (eg: d50 0.2um).

Even hard products can be ground, wet products can be ground and dried at the same time without any additional drying process.

Features and advantages

The jet velocity can reach 1,200 m/s, which is 3-4 times more efficient than the traditional jet mill.

The fineness of grinding materials can reach nanometer level

Narrower particle size distribution

When used in titanium dioxide, it ensures the dispersibility of TiO2 aggregates

Proprietary wear protection system, pollution-free design, easy to clean, can be crushed by high-pressure steam, hot air

It is safe in the process of processing flammable and explosive powders (such as coal/organic matter, etc.).

It is especially suitable for materials with crushing requirements. The instantaneous crushing power of the steam jet mill is large (during the crushing process of mica, the flake-shaped large-diameter ratio, high flatness, and ultra-lightweight can be achieved).

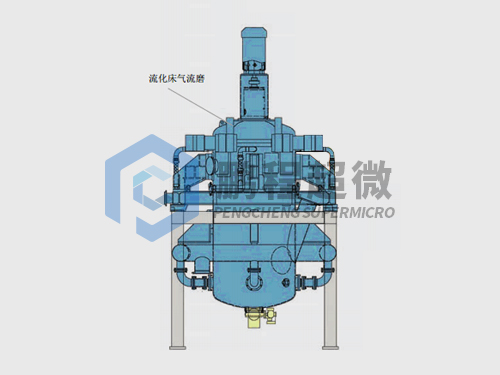

working principle

The steam jet mill is a jet mill that uses superheated dry steam as the grinding medium to crush materials. The superheated dry steam is accelerated by the Laval nozzle to obtain a supersonic airflow, and the materials are driven by the high-speed airflow to collide and crush each other. After the crushed materials are classified, those with qualified fineness enter the collection system for collection, and the unqualified materials are returned to the high-temperature steam crusher to continue crushing. The crushing production process is dry crushing, which is suitable for high temperature resistant ultrafine materials of soft and hard materials. The transmission part of the steam jet mill adopts sealed circulating cooling technology to ensure the continuous operation of the system.

use

It is applied to nanomaterials, titanium dioxide, ceramic powder, non-metallic minerals, chemicals, new materials, etc. It is suitable for dry ultra-fine grinding of various brittle, crystalline, heat-sensitive, and various hardness materials.

Specifications

|

Specifications |

Jet-s100 |

Jet- s300 |

Jet -s500 |

Jet-s 1000 |

Jet-s 2000 |

Jet-s 3000 |

Jet-s 5000 |

|

Product particle size d97:um |

0.3~50 |

||||||

|

Production capacity kg/h |

5~100 |

10~300 |

20~500 |

50~1000 |

100~2000 |

150~3000 |

300~5000 |

|

Steam consumption kg/h |

50-100 |

150-300 |

250-500 |

500-1000 |

1000-2000 |

1500-3000 |

2500-5000 |

|

Pressure Mpa |

1.0~10 |

||||||

Note: Based on calcium carbonate, the above is for reference only.