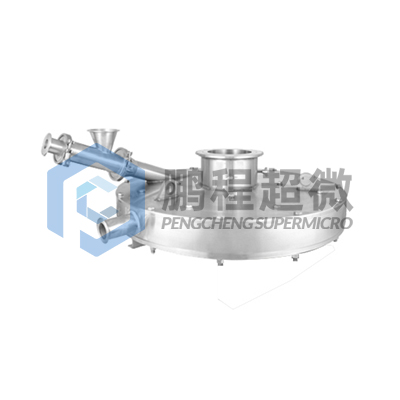

The FEM-Q pharmaceutical jet mill is mainly used in the pharmaceutical, cosmetic and chemical industries. In the crushing industry, we have our own unique professional technology and related equipment, as well as many years of production experience. This enables us to become a professional equipment supplier and Provide cutting-edge crushing technology solutions.

We design the production system in our own production workshop and can provide high-level on-site technical and skill consulting services. Our team includes experienced engineers, technicians, transfer workers, debuggers, etc., which are the solid backing for our business success.

Based on the above, today's Pengcheng Supermicro can provide advanced medical powder jet mill system. We have advanced spiral jet mill technology. This is a huge leap. We have been tirelessly pursuing progress and innovation.

Features and advantages

●The high-performance control design, many mechanical pulverizers that exceed the economical fineness limit, the micro-powder machine can continuously produce particles as small as 0.25 microns.

●•Support FDA-verified documents (IQ/OQ/PQ).

The crushed material can have a particle size distribution like "Gaussian curve"

● Consistent and tight particle size distribution, better suspension, dispersion and absorption

●It is convenient for manual disassembly, and no tools are needed to realize cleaning and sterilization.

● Pollution-free design can be ground into nano-level powder

●No heat generation: It is suitable for processing heat-sensitive materials.

●Easy for cleaning, product replacement or sterilization.

working principle

The grinding zone of FEM-Q pharmaceutical jet mill is in the central chamber of jet mill, and the grinding process does not involve grinding media. The powder material enters the flat cylindrical crushing box at a subsonic speed of about 50 meters per second under the action of compressed air or nitrogen from the tangential direction, and then is continuously accelerated to 300-400 under the action of the peripheral airflow nozzle M/s, and form a spiral motion trajectory. When the slower material that has just entered the crushing box hits the accelerated material on the spiral motion trajectory, it will collide to achieve the crushing effect. The centrifugal force will cause the larger particles to move around the crushing box, while the smaller particles will be discharged from the middle outlet of the crushing box along with the air flow. This crushing process is carried out at low temperature (no heat generation), which is similar to that of others on the market. Compared with similar equipment, it has the unique lowest air consumption. The material rotates in the cavity at high speed along the set direction, so that the materials collide and rub against each other and grind the materials. Centrifugal force keeps the larger particles in the jet mill crushing area until they reach the required fine particle size. The centripetal force drags the required particles to the static classification zone, and after reaching the required particle size, enter the collector.

use

It is suitable for dry ultra-fine grinding of various brittle, crystalline, heat-sensitive, medium and low hardness materials. Used in chemical, pharmaceutical, food and other industries, with high yield and no dust spillage.

technical parameter

| Specifications |

FEM-Q1 |

FEM-Q2 |

FEM-Q3 |

FEM-Q4 |

FEM-Q5 |

FEM-Q6 |

|

Feeding granularity mm |

<1 |

<1 |

<2 |

<3 |

<3 |

<3 |

|

Product particle size d97:um |

1~45 |

1~45 |

1~45 |

2~45 |

2~45 |

2~45 |

|

Production capacity kg/h |

0.5~5 |

1.0~20 |

4~40 |

15~100 |

20~140 |

40~500 |

|

Air consumption m3/min |

1 |

2 |

3 |

6 |

10 |

20 |

|

Air pressure Mpa |

8-10 |

|||||

|

Installed power kw |

50 |

70 |

140 |

280 |

350 |

570 |

Note: Based on calcium carbonate, the above is for reference only.