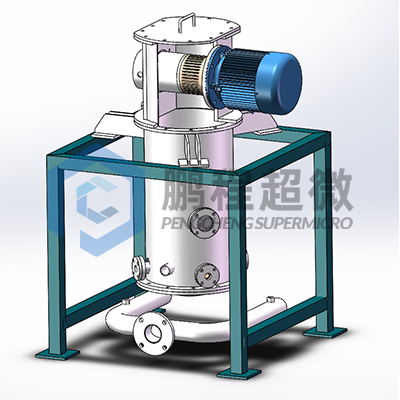

JET-H fluidized bed jet mill is a raw material self-grinding system, which is an ideal non-polluting, high-purity pulverizing system.

Performance characteristics

The fineness can reach d98<2.0 µm (based on calcium carbonate)

Suitable for crushing, disintegrating, spheroidizing and shaping various powders with Mohs hardness below 10;

High-quality products: 99.999% high-purity products can be obtained;

Because of its special non-medium spray crushing, it is especially suitable for ultrafine crushing of high-purity materials;

The temperature of the grinding chamber is used to grind materials with constant temperature (20°C) cold air, which has an excellent crushing effect on heat-sensitive materials;

The grading wheel automatically separates materials through airflow without coarse particles. There are carbon steel, special steel, stainless steel, alumina and zirconia ceramics.

Wear-resistant protection: A variety of wear-resistant protection materials can be selected inside the equipment, such as alumina, zirconia, and organic materials;

Protect the bearing by compressed air

Completely self-grinding, zero wear and zero pollution

Easy to clean and maintain

High product consistency

Optional configuration provided: explosion-proof, vibration-proof and moisture-proof design, inert gas protection cycle process to ensure continuous safe and stable operation of flammable, explosive and oxidizing materials, airtight device, wear-resistant configuration

working principle

The raw material powder uses fluid energy-compressed air to rapidly expand the gas through the Laval nozzle or gas grinding system, and move the animal material at high speed. The particles close to the speed of sound collide and grind the particles, resulting in smaller and smaller particles. The centrifugal force keeps the larger particles cyclically colliding in the jet mill until they reach the required fineness. The centripetal force drags the required particles to the grading wheel, and after reaching the correct particle size, they enter the cyclone trap or dust collector with the air flow to be collected. The material is basically self-grinding by the grinding energy generated by the airflow alone, and the machine itself has no wear.

Application field

Ceramics (such as oxides, carbides, nitrides and silicates), rare earths (such as neodymium iron boron, cerium oxide, samarium cobalt, etc.), high-purity non-polluting products (such as silica gel, phosphors, etc.), insecticides, Resins, waxes, pigments and dyes, mineral powders (such as talcum powder), chemicals, Chinese herbal medicine, cosmetics, food, flame retardants, printer powder, activated carbon, etc.;

Specification model

|

Specifications |

JET-H06 |

JET-H10 |

JET-H20 |

JET-H40 |

JET-H60 |

JET-H80 |

JET-H120 |

|

Feeding granularity mm |

<5 |

<5 |

<5 |

<5 |

<5 |

<5 |

<5 |

|

Product particle size d97:um |

2~75 |

2~75 |

2~75 |

2~75 |

3~75 |

4~75 |

4~75 |

|

Production capacity kg/h |

4~50 |

8~80 |

20~300 |

40~500 |

80~800 |

100~1200 |

150~2000 |

|

Air consumption m3/min |

6 |

10 |

20 |

40 |

60 |

80 |

80 |

|

Air pressure Mpa |

10 |

||||||

|

Installed power kw |

50 |

70 |

140 |

280 |

350 |

570 |

850 |

Note: Based on calcium carbonate, the above is for reference only.