Technical characteristics

Using low-temperature water circulation and air cooling, the crushing temperature is low, and the equipment is less worn.

Easy maintenance and simple operation

There is no stock in the crushing chamber and the output is high.

All are made of wear-resistant steel and have a long service life.

Negative pressure sealing operation, dust-free and environmentally friendly

This machine is equipped with an air feeding and discharging device to ensure uniform cooling of materials and fast cooling speed.

Adjustable feeding speed

PCM low-temperature plastic grinder has the characteristics of high output and low energy consumption. It is used for grinding and crushing the powder processing of other materials such as polyethylene PE, polypropylene PP, polystyrene PS, ABS and so on.

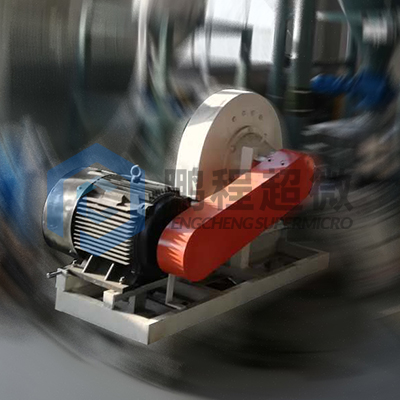

working principle

The raw material particles enter the PCM low-temperature plastic pulverizer from the feeder. The high-speed rotating pulverizing disk and the fixed disk make the material rubbed and pulverized into fine powder, and then enter the dust collector for collection. The qualified fine powder is sieved and collected by the screening machine, and the coarse powder is returned to the mill for secondary crushing.

Application field

Dipping powder, plastic powder, PVC powder, plastic powder, PC powder, PVC powder, plastic lining powder, powder coating powder, rotomolding powder, etc.;

Specifications

| Model |

PCM-400 |

PCM-500 |

PCM-600 |

|

Grinding size (mesh) |

5-200 |

||

|

Power (kw) |

22 |

37 |

55 |

|

Processing capacity (kg/h) |

100-250 |

200~400 |

300~500 |

|

Host weight (kg) |

1300 |

1600 |

2000 |

Note: based on calcium carbonate