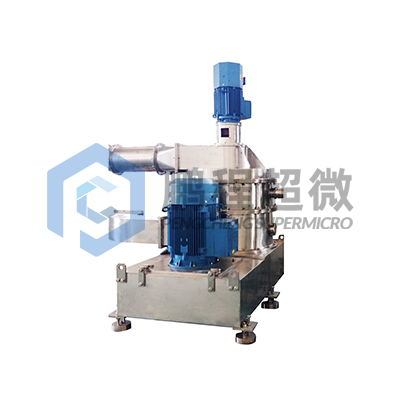

CSM-V superfine crusher is suitable for all materials with medium hardness and fibrous and tough materials. The unique flow field design and excellent hierarchical structure make the particle size control strong. Pengcheng Supermicro's mechanical grinding and crushing equipment can provide customers with various specifications and fineness requirements.

When changing products, the cabinet is easy to open, and the equipment can be cleaned quickly and conveniently.

Fine grinding products

Technical features:

Material fineness d97 8 µm to d97 150 µm (based on calcium carbonate)

Suitable for crushing of D50 products between 1-45 µm

Airflow grinder with integrated dynamic air classifier

Through the interaction of air flow and particles, particles and particles are crushed, and the fineness range is adjusted through the classification wheel

To achieve the desired material fineness by adjusting the air intake and the speed of the grading wheel

The final material has an excellent particle size distribution without large particles

Even if it is used for high-hardness materials, the equipment can run under high wear resistance and low pollution

Reasonable layout of grinding area and grading wheel to get the best material circulation

Various design styles: compression-resistant, air-tight, wear-protected

working principle

The CSM-V superfine grinder is also called a classifying mill, which is a combination of an impact mill and a built-in classifying wheel. The material is ground between the annular grinding track and the rotating grinding disc. The built-in grading wheel can directly separate fine products, avoiding the dual configuration of grinding and grading equipment, thereby making the production process more stable and economical. By increasing or decreasing the speed of the classifier, the particle size can be easily adjusted without turning off the mill to achieve the desired product fineness. Through this highly developed classification technology, the vertically placed classification wheel rotates horizontally to ensure optimal particle gradation distribution.

Application field

Food, medicine, chemical dyes, pigments, cosmetics, resins, phosphates, raw materials, flame retardants, white carbon black, plastics, feed, plant fibers, regenerated rubber, PE wax, ceramics, etc.;

Specifications

|

Model/Parameter |

CSM-200V |

CSM-300V |

CSM-410V |

CSM-510V |

CSM-650V |

CSM-800V |

CSM-1000V |

CSM-1200V |

|

|

Matching power (kw) |

Shatter disk |

2-4 |

5.5-7.5 |

11~15 |

22~30 |

45~55 |

90~110 |

110~132 |

132-160 |

|

Grading impeller |

0.75 |

1.5 |

2.2 |

5.5 |

7.5 |

11 |

15 |

30 |

|

|

Feeder |

0.37~2.2 |

||||||||

|

Speed (r/min)

|

Shatter disk |

12000 |

7500 |

5400 |

4600 |

3500 |

2700 |

2200 |

1900 |

|

Grading impeller |

11000 |

6800 |

5500 |

4200 |

3400 |

2800 |

2200 |

1900 |

|

|

Crushing particle size D97um |

2-150 |

2-150 |

2-150 |

3-150 |

3-150 |

5-150 |

6-150 |

6-150 |

|

|

Output (kg/h) |

10-80 |

60-500 |

60-500 |

60-1000 |

300-2000 |

450-2700 |

680-4000 |

800-6000 |

|

Note: based on calcium carbonate